After installation, the Lansitec Bluetooth Beacon with Accelerometer continuously captures data regarding vibrations, acceleration, and rotational speed from the motor and pump. The accelerometer detects even the slightest irregularities in the mechanical behavior of the system. Here’s a more detailed step-by-step breakdown of the data flow:

Sensor Data Capture:

The accelerometer monitors three-axis vibrations and measures rotational speed to create a precise profile of the motor and pump’s operational behavior. It captures data such as:

Changes in vibration intensity (indicative of misalignment, wear, or imbalances).

Rotational speed variations, helping identify any mechanical load issues.

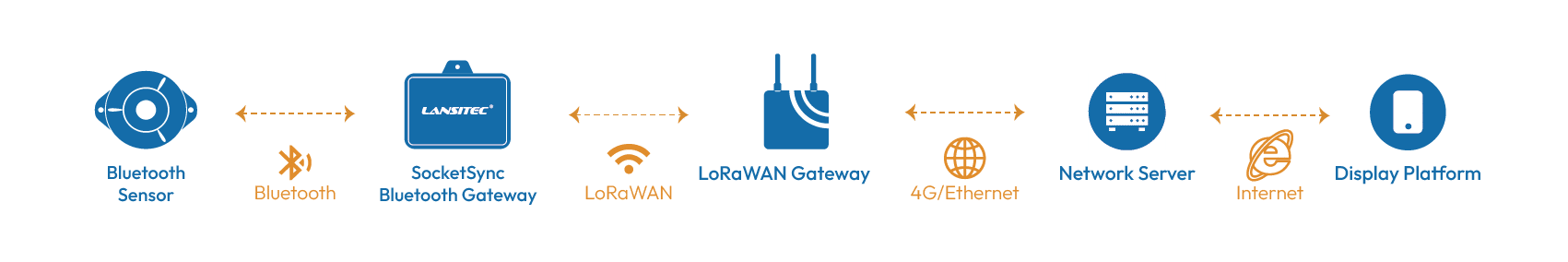

Bluetooth Transmission:

The sensor wirelessly transmits this real-time data using Bluetooth 5.0. This version of Bluetooth ensures low-energy consumption and stable connections over a range of up to 100 meters, ideal for covering the distance between the motor-pump system and the gateway located within or near the pump house.

Gateway Data Aggregation:

The Lansitec Socket Sync Bluetooth Gateway serves as the intermediary device. It receives the Bluetooth signals from multiple sensors simultaneously and consolidates the data. The gateway’s ability to support multiple connections ensures scalability for monitoring several motor-pump pairs at once.

LoRaWAN Transmission to the Cloud:

Transmission of data from the gateway to the cloud is done using LoRaWAN technology, allowing for data to be successfully sent over extended distances. The low-power, wide-area network capability of LoRaWAN is crucial for transmitting data reliably in industrial locations or remote pump houses with unreliable or unavailable conventional internet connections. LoRaWAN effectively sends data packets over long distances without using a lot of power, which is crucial for installations relying on solar or battery power.

Cloud Processing and Alerts:

Next, the information is sent to a cloud-based system, where it is stored and analyzed immediately. Machine learning algorithms or predetermined thresholds can identify unusual patterns in the vibration or rotational data, raising a red flag for possible problems. If the system detects irregularities like too much shaking or sudden shifts in speed, it immediately sends an alert to the user through a mobile app or web dashboard.

Notifications and Maintenance Tasks: These notifications, along with all operational information, are shown in a user-friendly interface, offering practical insights. Users can track trends, analyze past information, and, most significantly, get immediate alerts for possible issues. This enables prompt action to be taken, whether it be setting up preventative maintenance or looking into an unusual reading before it turns into a significant issue.

This smooth data transmission guarantees ongoing real-time observation of motor-pump systems, enabling maintenance crews to respond to early alerts, minimizing downtime, and enhancing operational effectiveness. Monitoring and Maintenance Workflow